Advanced EMC testing solutions for a connected world

In a world driven by electronic devices, ensuring electromagnetic compatibility (EMC) is more critical than ever. The primary benefit of a robust design and testing process is bringing a compliant product to market faster. Every electronic device must function reliably in its electromagnetic environment without causing interference or being susceptible to it.

At MVG, we provide cutting-edge EMC measurement equipment designed to help you meet regulatory requirements.

Our comprehensive portfolio includes a wide selection of standard and customizable EMC products to build the appropriate test environment for accurate and repeatable emission and immunity testing results, and ensure the process toward final product certification.

A complete range of test chambers and shielding solutions

The accuracy of EMC testing heavily relies on the quality of the test environment. We offer an array of high-performance solutions, from compact shielded enclosures to full-vehicle EMC test enclosures. Our expertise covers two core technologies:

Our EMC anechoic and semi-anechoic chambers are engineered for precision radiated emissions and immunity testing, providing an interference-free environment that simulates an open-area test site.

For immunity testing where a uniform field is required, our reverberation chambers offer an efficient and effective choice. This type of facility is essential in the final certification process.

For immunity testing where a uniform field is required, our reverberation chambers offer an efficient and effective choice. This type of facility is essential in the final certification process.

Alongside these primary electromagnetic compatibility test solutions, we specialize in a variety of shielding technologies to isolate any electric or electronic device under test, including:

MVG shielding technologies

RF shielded rooms : Modular and customized rooms for an interference-free environment.

Shielded test cells and shielded cabinets : Compact options for testing smaller devices.

Shielded containers : Commonly used for either MRI, EMC or EMP applications.

Shielded doors : Ensuring complete integrity of the shielded setup, the high performance shielding results are achieved using a knife edge closure system and beryllium copper finger contact strips. Swing doors with pivoting hinges ensure the durability of the fingerstock gaskets mounted in the door frames. Sliding doors are designed to provide the same extended shielding effectiveness and performance.

Our test facilities help you conduct pre-compliance or compliance testing for your devices in preparation for standards like CISPR, MIL-STD, and FCC. Whether you need to assess a component's vulnerability to ESD (Electrostatic Discharge) or measure its radiated emissions, we provide the reliable shielded electromagnetic environment and equipment you need.

High-performance antennas and absorbers for accurate testing

To complement MVG test environments, we manufacture essential components to assist in electromagnetic compatibility emission and immunity testing.

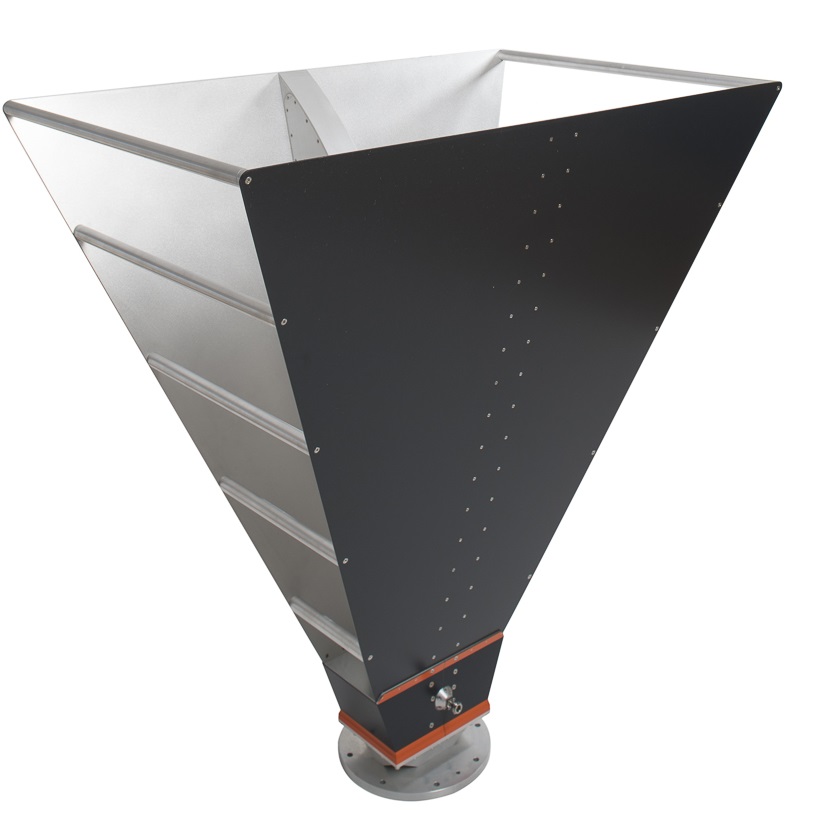

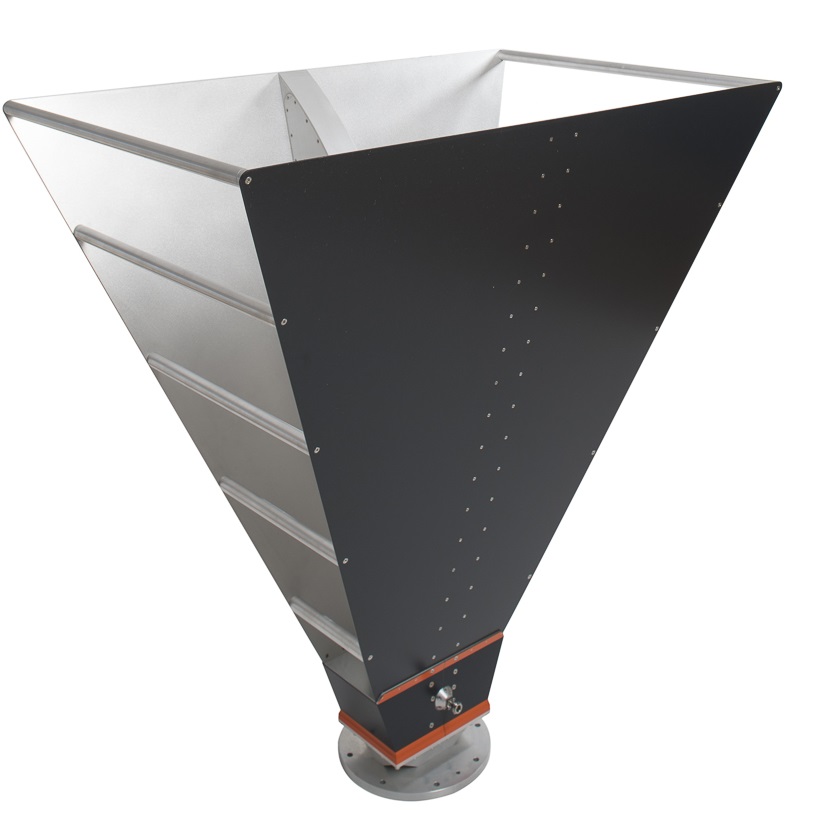

Our selection of EMC antennas cover a broad frequency range, ensuring you can precisely measure any electromagnetic field or unwanted signal. A quality antenna is a crucial part of any setup for the purpose of conducting emission and immunity testing.

Our selection of EMC antennas cover a broad frequency range, ensuring you can precisely measure any electromagnetic field or unwanted signal. A quality antenna is a crucial part of any setup for the purpose of conducting emission and immunity testing.

The performance of an anechoic enclosure is defined by its absorbers and shielding. We offer advanced RF absorbers designed to manage electromagnetic waves so the test environment accurately simulates “free-space” conditions and prevents unwanted reflections. Electromagnetic wave absorbers ensure the chamber meets the field uniformity and site attenuation criteria specified in standards.

designed to manage electromagnetic waves so the test environment accurately simulates “free-space” conditions and prevents unwanted reflections. Electromagnetic wave absorbers ensure the chamber meets the field uniformity and site attenuation criteria specified in standards.

Let our expert team guide you to the best antennas and absorbers for your EMC application.

Frequently Asked Questions (FAQ) about EMC Test and Measurement Solutions

What is EMC testing and why is it important?

Electromagnetic Compatibility (EMC) testing ensures that an electric or electronic device does not generate excessive electromagnetic interference (its emission level) and is not unduly affected by external phenomena (its immunity). It is a mandatory step for most electronic products to obtain certification and be sold legally, guaranteeing their safety and reliability.

Why does an EMC chamber require shielding?

A shielded chamber ensures a controlled, interference-free space for EMC testing. It blocks external signals from disturbing sensitive measurements and contains the strong electromagnetic fields generated during immunity tests. This guarantees accurate, repeatable results in line with international compliance standards, while also protecting the outside environment from unintended emissions when conducting tests.

What is the main benefit of pre-compliance testing?

The main benefit of pre-compliance testing is identifying potential EMC issues early in the design process. This allows you to fix a problem on a device before incurring the high costs of official certification testing, saving significant time and money.

Which standards, like FCC, require EMC compliance testing?

A wide range of industries require rigorous EMC testing to meet specific standards from bodies like the FCC in the United States, or CE in Europe. This applies to nearly any electronic device, from automotive components and medical equipment to consumer electronics.

Can you help with a specific testing question, like for ESD?

ESD testing in EMI refers to the electromagnetic interference effects caused by electrostatic discharges and the immunity testing required to ensure devices function properly when exposed to them.

What is the difference between a shielded room and an EMC chamber?

A shielded room is a room enclosed with conductive materials to block electromagnetic fields from entering or leaving. It provides a quiet RF environment, so ensures isolation, but by itself does not control internal reflections. It is used for simple pre-compliance testing, troubleshooting, or test setups where shielding alone is enough (e.g., TEMPEST rooms for secure communications).

An EMC Chamber is a shielded room that is further equipped with absorber materials (ferrite tiles, pyramidal foam, or hybrids) and specialized testing infrastructure. It provides a standardized test environment for EMC compliance measurements. It is used to control reflections, to simulate free-space conditions. It is designed for both emission and immunity testing.

For immunity testing where a uniform field is required, our

For immunity testing where a uniform field is required, our  Our selection of

Our selection of  designed to manage electromagnetic waves so the test environment accurately simulates “free-space” conditions and prevents unwanted reflections. Electromagnetic wave absorbers ensure the chamber meets the field uniformity and site attenuation criteria specified in standards.

designed to manage electromagnetic waves so the test environment accurately simulates “free-space” conditions and prevents unwanted reflections. Electromagnetic wave absorbers ensure the chamber meets the field uniformity and site attenuation criteria specified in standards.